Quality Control

Export City – Quality Control

With the development of business and the increasingly complex technical requirements of our customers, we noticed the need for the formation of a quality management department. Bearing in mind that quality covers all aspects of our business processes, it is crucial to strengthen this department through the two most important phases:

Product Quality Management and Data Analytics

This phase includes product quality control through all production steps.

Product and System Quality Management

This segment includes audit activities, supplier quality assurance (SQA), and customer quality assurance (CQA).

We are committed to ensuring that every product undergoes a process of quality control and assurance to continuously improve our finished products year after year. This allows us to meet the highest standards and expectations of our clients.

Miloš Tomaš

quality control Department Manager at Export City

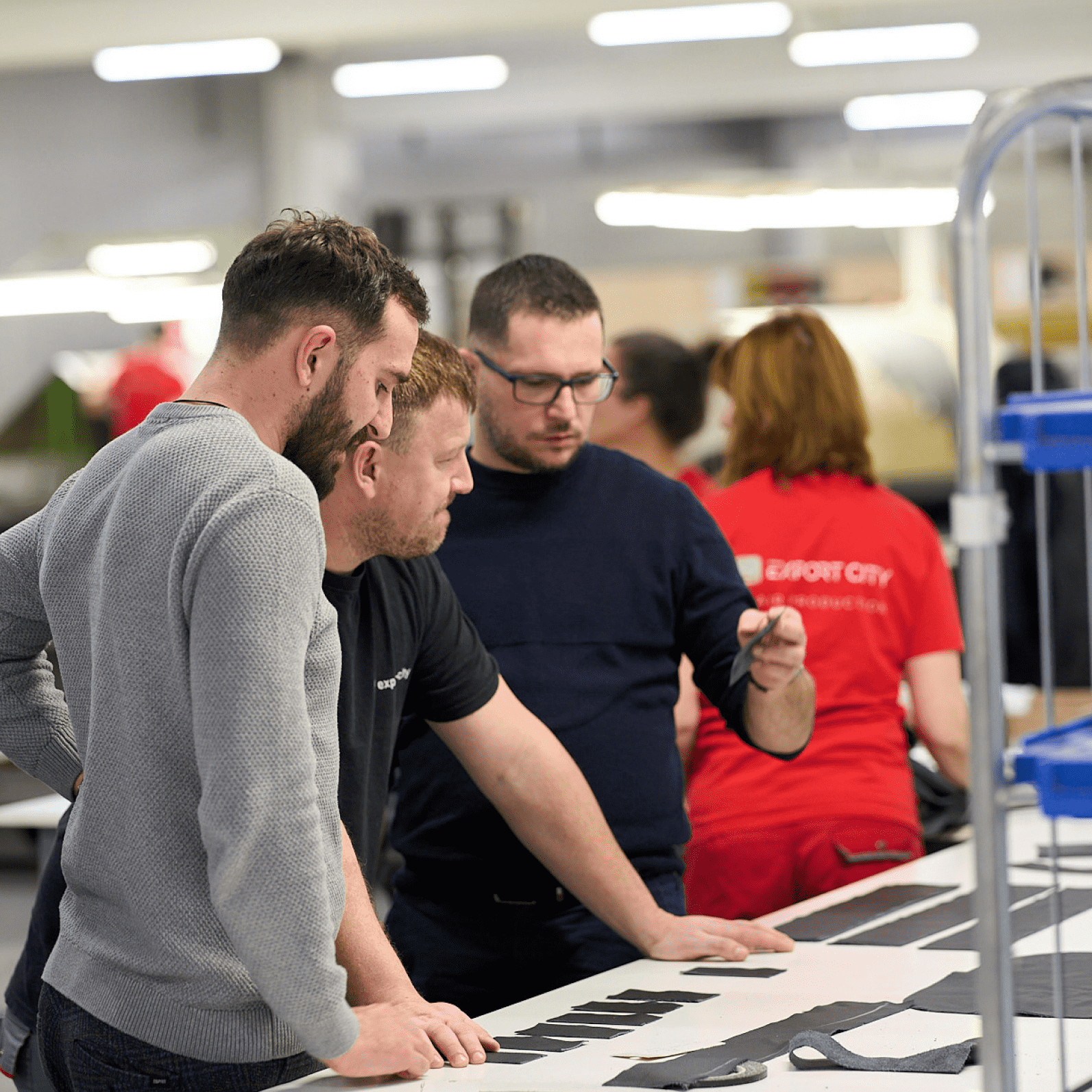

Final Control in Each Department

Every department in our company has a final inspection where each product piece, without exception, is carefully examined before moving further in the production chain, ensuring a high standard of quality at every step of the process.

Identifying Problems and Errors in the Earliest Stages

It is important to point out that for each department we have pre-defined forms for possible errors. These forms are elaborated in detail and are regularly revised on a daily, weekly, monthly and quarterly basis. This practice ensures that problems are identified and solved at the earliest stage, and that the same problems do not recur.

Our ultimate goal is to reduce the number of repairs on a daily basis, and to achieve as few complaints as possible from year to year.

High Standard of the Production Process

This systematic approach allows us to continuously improve processes and ensure a high standard of quality at all stages of production.