ABOUT US

Export City d.o.o. is a family-oriented company. It was founded and started operating in 2004 in Prnjavor (BiH).

We are specialised in producing upholstered chairs and seating office furniture with annual delivery of 350.000 units. Success in business operations is based on the business cooperation with reputable buyers from abroad that recognised our quality.

The company employs 300 employees and production is carried out in their own facilities of 25.000 m2. They are new and equipped with modern equipment made by leading world manufacturers.

Through continuous investing in the knowledge and technology we provide our employees with high quality and safe working conditions, and as a result we try to be long-term, high quality and reliable partner to our employees. Everyday improvement is possible only with the help of qualified and motivated team aware that only with hard work we can be different from the competition. So we pay the most attention to education, improvement and development of our employees. Such improvement represents the success of the entire system.

With the aim of improvement of quality, we continuously implement new technologies and invest in high quality production management allowing us direct impact on the quality of product and productivity of work. All materials we use in the production own appropriate national and foreign attestations and with that we fully fulfil high-standard requirements for the products to be launched onto the EU and GB market.

Mission and vision

Our mission is to follow trends and meet the needs of our buyers through production of high quality products. We also try to be socially responsible company ready to set an example of responsibility, successfulness and business operations in the best business manner with our business operations, relationship with the community, environment, our buyers and partners.

Our vision is to be leading chair manufacturer and other upholstered seating furniture in this part of Europe through our experience, quality and responsibility recognised by leading European brands.

MANUFACTURING

Textile sewing and tailoring

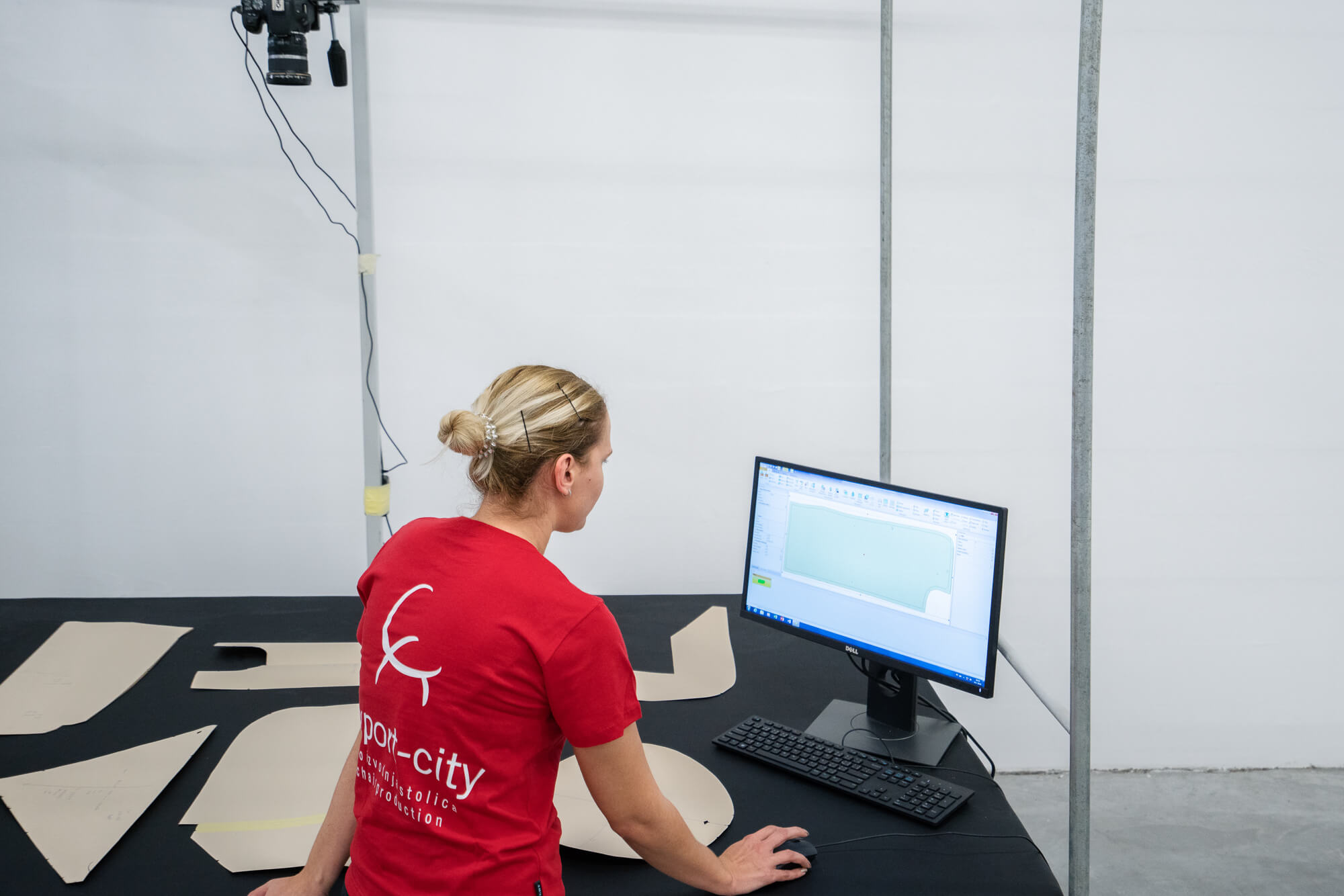

Textile sewing and tailoring department is equipped with latest CNC cutters made by Gerber Technology and Bullmer Gmbh. The cutters are equipped with video cameras and upgraded with software (automatch) so they can fit pieces that are cut including cubes, rhombi and circles.

Leather sewing and tailoring

Leather tailoring department is equipped with latest CNC cutters made by Gerber Technology which cut pieces of lether very precisely and with little waste.

The capacity of leather sewing and tailoring department is 30.000 square meters per month.

Sewing room

Sewing room contains 100 sewing machines made by Durkopp Adler AG and several of them are special in order to meet the special requirements of our clients. Also, we would like to point out a machine made by Styrteknik Europe AB that is specialized for systems used for sewing circles and lockstitches over material whose thickness is up to 17 cm.

Processing of sponge

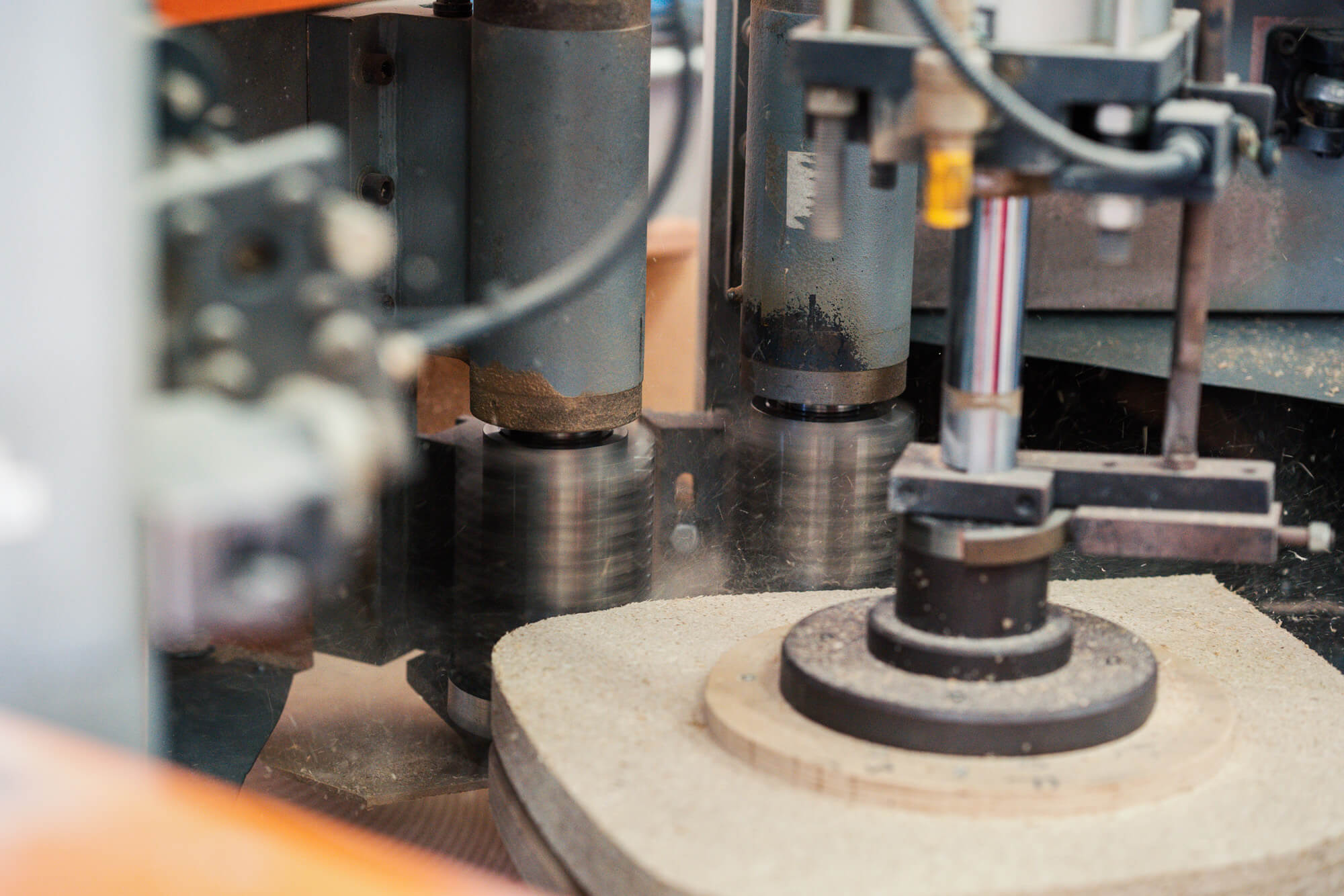

The department for shaping sponge is equipped with several CNC machines manufactured by Fecken-Kirfel GmbH&Co. We also own several special machines that allow us to create every shape of polyurethane foam we want, from dents and slopes to 3D shapes. Sponges we use in our manufacturing are purchased exclusively from verified suppliers that issue appropriate certificate for every type of sponge.

Polyurethane seat casting plant

The polyurethane seat casting plant is a relatively new project, but we have managed to master the production in a short time, so we are able to offer a very high quality product that meeting European standards. All the raw materials are procured from the EU exclusively, which is certified. The plant is equipped with injection molding machines, Cell Crusher …

Processing of wooden parts

The department is equipped with woodworking machines used for woodworking during which we process particle board, pressings, MDF and other materials used further in woodworking.

Upholstering

There are 60 upholsterers that have many years of experience and that are employed in the upholstering department and they are responsible for making every product unique by their quality and look which is a condition that needs to be fulfilled for the company to achieve their goals. Special processes of gluing and heating upholstered parts of chairs in thermal ovens occur in that department in order for materials such as leather or canvas to be glued to the sponge.

In the final phase contains of examination, packing and labelling finished products with barcodes.

Each product is labelled with date of production so if a mistake occurs a cause can be determined in order for the mistake not to be repeated.

Warehouse

Warehouse takes the space of 3000 square meters. The goods are stored on shelves in order to avoid any kind of damage and to ease its use.